Our Story

Plutosemi Co., Ltd

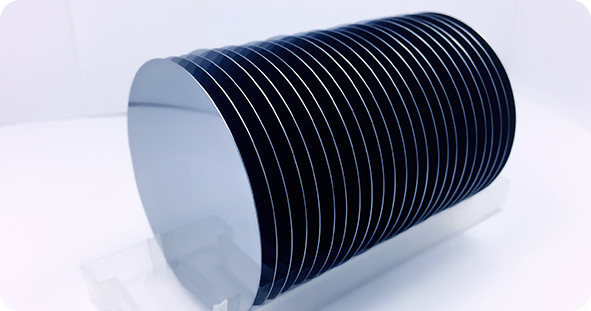

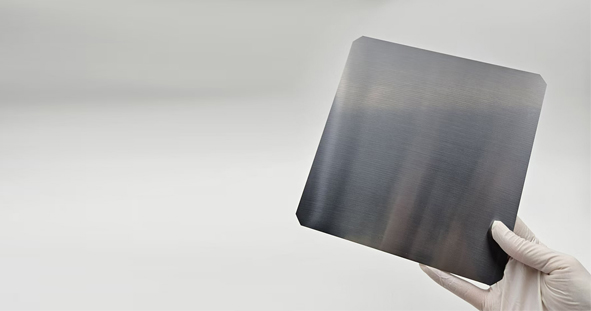

Founded in 2019 and based in Foshan Nanhai, Plutosemi Co., Ltd. specializes in high-performance semiconductor materials. As an industry leader, we offer advanced production capabilities and high-quality products such as silicon wafers and SOI, featuring high precision for diverse applications. Our one-stop services and customized solutions meet specific customer needs. Widely used in China, Europe, and the USA, we maintain strong partnerships with renowned international companies, upholding the philosophy of "Customer First, Quality Foremost".

Product Center

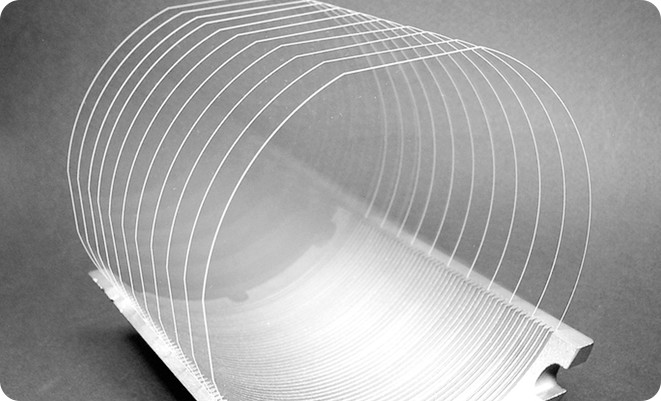

Glass Wafer

Exhibition

Innovation

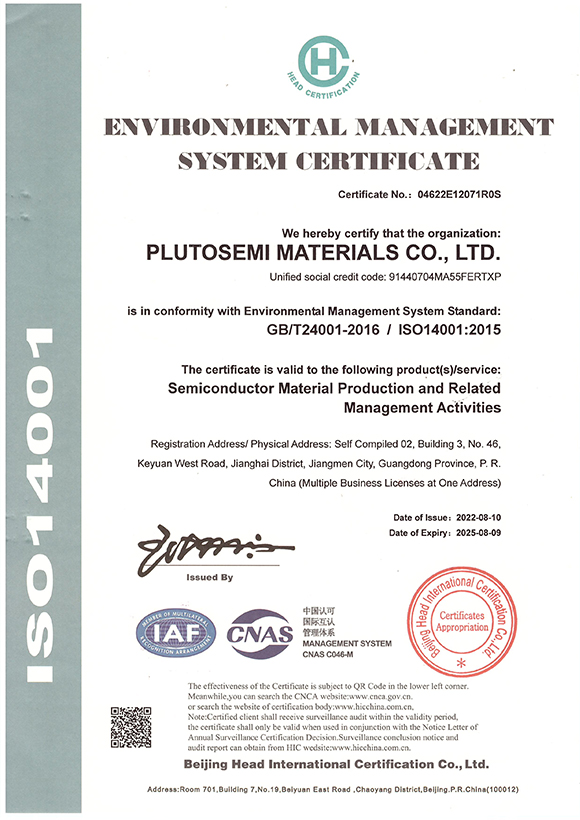

Certificate

The company maintains industry-leading standards with certifications in high-performance semiconductor materials R&D, production, and sales, supporting its position as a leader in the semiconductor materials sector.