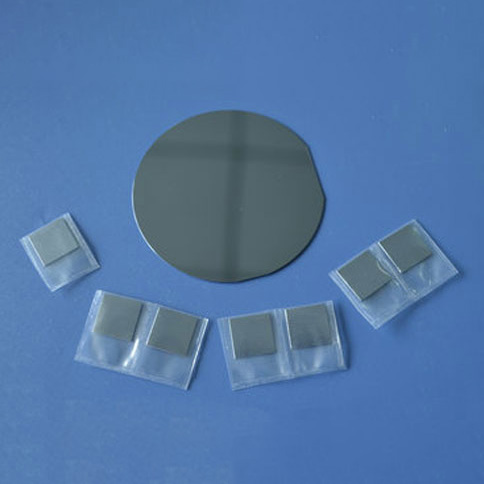

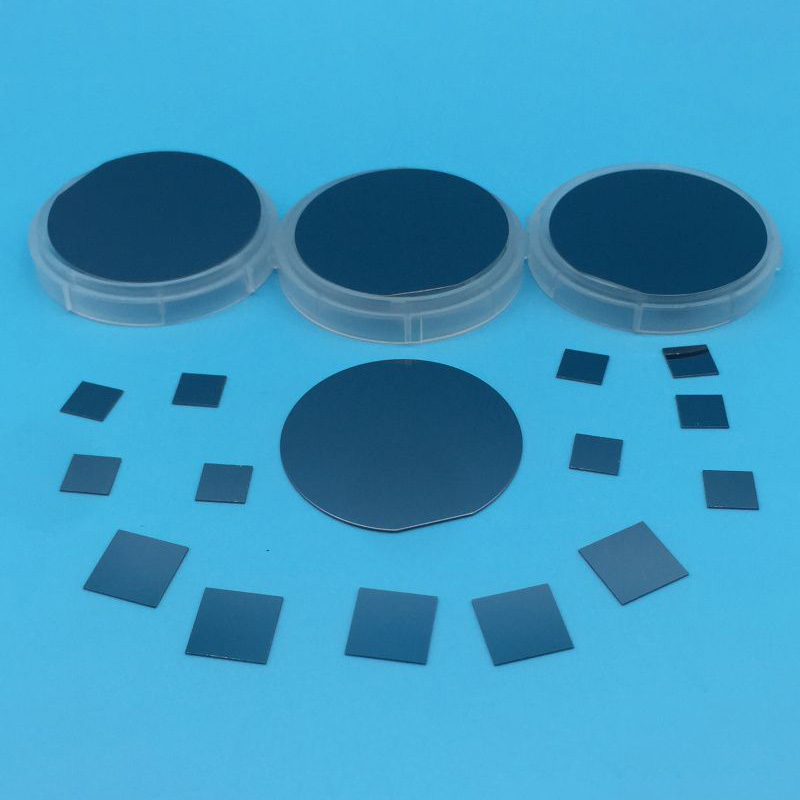

Gallium Oxide Wafer

Compound Semiconductor Wafers

-

+86-17701852595 WhatsApp

-

sales@plutosemitech.com Email

Gallium oxide (Ga2O3) is an inorganic compound. It is a wide bandgap semiconductor and a transparent oxide semiconductor material that has broad application prospects in optoelectronic devices and is used as an insulating layer for GA-based semiconductor materials and as an ultraviolet filter. It can also be used as an O2 chemical detector.

gallium oxide wafer is a high-performance semiconductor material with a wide bandgap, making it ideal for use in power electronics, optoelectronics, and ultraviolet devices. Known for its high thermal stability, transparency, and excellent electrical properties, Ga2O3 wafers are commonly used in ultraviolet detectors, O2 chemical sensors, and as an insulating layer in Ga-based semiconductor materials. This material has significant potential in high-power applications, contributing to the development of more efficient devices. As a leading China gallium oxide wafer manufacturer, we specialize in producing high-quality Ga2O3 wafers tailored for a variety of advanced applications.

Product Standard:

| Product Name | Size | Orientation |

| Ga2O3 substrate wafer | 10.5mm*10mm | 010 |

| Ga2O3 substrate wafer | 10mm*5mm | 010 |

| Ga2O3 substrate wafer | 2 inch | 100 |

| Ga2O3 substrate wafer | 4 inch | 100 |

| Ga2O3 substrate wafer | 6 inch | 100 |

Gallium Oxide Wafer Specifications

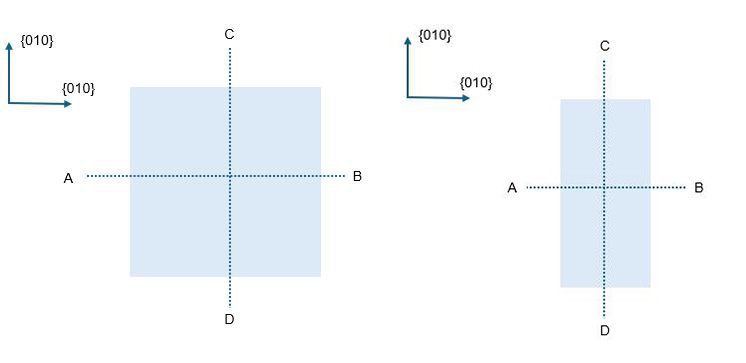

Specifications of Square β-Ga2O3 substrate

| Item | Specifications | ||

| Orientation | < 100 > | ||

| Dopant | UID | Sn | Mg/Fe |

| Resistivity | 1016~1017cm-3 | ~1018cm-3 | ≥1010Ω.cm |

| FWHM(arcsec) | ≤150 | ≤150 | ≤150 |

| BPD | <1×105cm-2 | ||

| Size | A-B | C-D | Thickness |

| 10mm | 10.5mm | 0.5(±0.02)mm | |

| 5mm | 10mm | 0.5(±0.02)mm | |

| Flat | The long side is < 010 > | ||

| Surface | DSP/SSP | ||

| Ra< 0.5nm | |||

| Offset angle< ±1° | |||

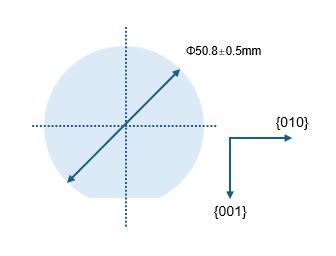

Specifications of 2 inch β-Ga2O3 substrate wafer

| Item | Specifications | ||

| Orientation | <100> | ||

| Dopant | UID | Sn | Mg/Fe |

| Resistivity | 0.1-0.9Ω.cm | 0.01-0.04Ω.cm | ≥1010Ω.cm |

| FWHM(arcsec) | ≤150 arc sec | ||

| BPD | <1×105cm-2 | ||

| Size | Diameter | Thickness | |

| 50.8±0.5mm | 650±20um | ||

| Flat | < 010 > | ||

| Surface | DSP/SSP | ||

| Ra < 0.5nm | |||

| Offset angle<±1° | |||

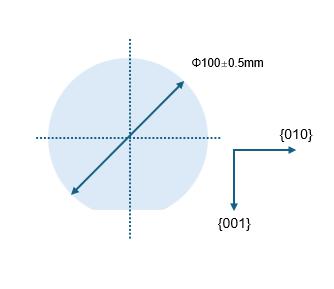

Specifications of 4 inch β-Ga2O3 substrate wafer

| Item | Specifications | ||

| Orientation | <100> | ||

| Dopant | UID | Sn | Mg/Fe |

| Resistivity | 0.1-0.9Ω.cm | 0.01-0.04Ω.cm | ≥1010Ω.cm |

| FWHM(arcsec) | ≤150 arc sec | ||

| BPD | < 1×105cm-2 | ||

| Size | Diameter | Thickness | |

| 100±0.5mm | 650±20um | ||

| Flat | <010> | ||

| Surface | DSP/SSP | ||

| Ra < 0.5nm | |||

| Offset angle<±1° | |||

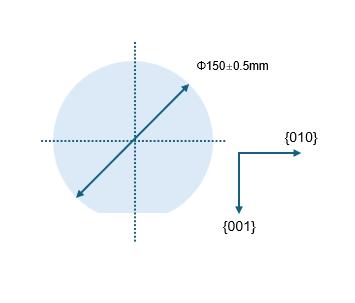

Specifications of 6 inch β-Ga2O3 substrate wafer

| Item | Specifications | |

| Orientation | <100> | |

| Dopant | UID | Sn |

| Resistivity | 0.1-0.9Ω.cm | 0.01-0.04Ω.cm |

| FWHM(arcsec) | ≤200 arc sec | |

| BPD | <1×105cm-2 | |

| Size | Diameter | Thickness |

| 150±0.5mm | 800±20um | |

| Flat | <010> | |

| Surface | DSP/SSP | |

| Ra < 0.5nm | ||

| Offset angle<±1° | ||

Gallium Oxide Wafer Features

1. Wide Bandgap: Ga2O3 has a wide bandgap of approximately 4.9 eV, making it suitable for high-power and high-voltage applications. It can operate at higher temperatures and voltages compared to traditional semiconductors.

2. High Thermal Stability: Ga2O3 wafers exhibit excellent thermal stability, allowing them to perform reliably under high-temperature conditions, which is critical for power electronics and other demanding applications.

3. Transparency in UV Range: Ga2O3 is transparent to ultraviolet (UV) light, which makes it ideal for use in UV detectors, sensors, and optoelectronic devices.

4. High Breakdown Voltage: The material's ability to handle high electric fields without breaking down is a crucial feature for high-power devices, such as power transistors and rectifiers.

5. Electrical Insulation: Ga2O3 wafers serve as an insulating layer for Ga-based semiconductors, enhancing the performance of devices by reducing current leakage and improving energy efficiency.

Gallium Oxide Wafer FAQ

What is Gallium Oxide (Ga2O3) wafer used for?

Ga2O3 wafers are used in high-power electronics, optoelectronics, ultraviolet detectors, O2 chemical sensors, and as insulating layers in Ga-based semiconductor materials.

What are the advantages of using Ga2O3 wafers over other semiconductor materials?

Ga2O3 offers a wide bandgap, high thermal stability, high breakdown voltage, and transparency in the UV range, which makes it ideal for high-power, high-voltage, and optoelectronic applications.

How does the wide bandgap of Ga2O3 benefit electronic devices?

The wide bandgap (4.9 eV) allows Ga2O3 to operate at higher voltages, temperatures, and power levels compared to conventional semiconductors, making it suitable for high-performance, energy-efficient devices.

What industries benefit from Gallium Oxide wafers?

Industries such as power electronics, automotive, telecommunications, environmental monitoring, and sensor technology benefit from Ga2O3 wafers due to their high efficiency and versatility.

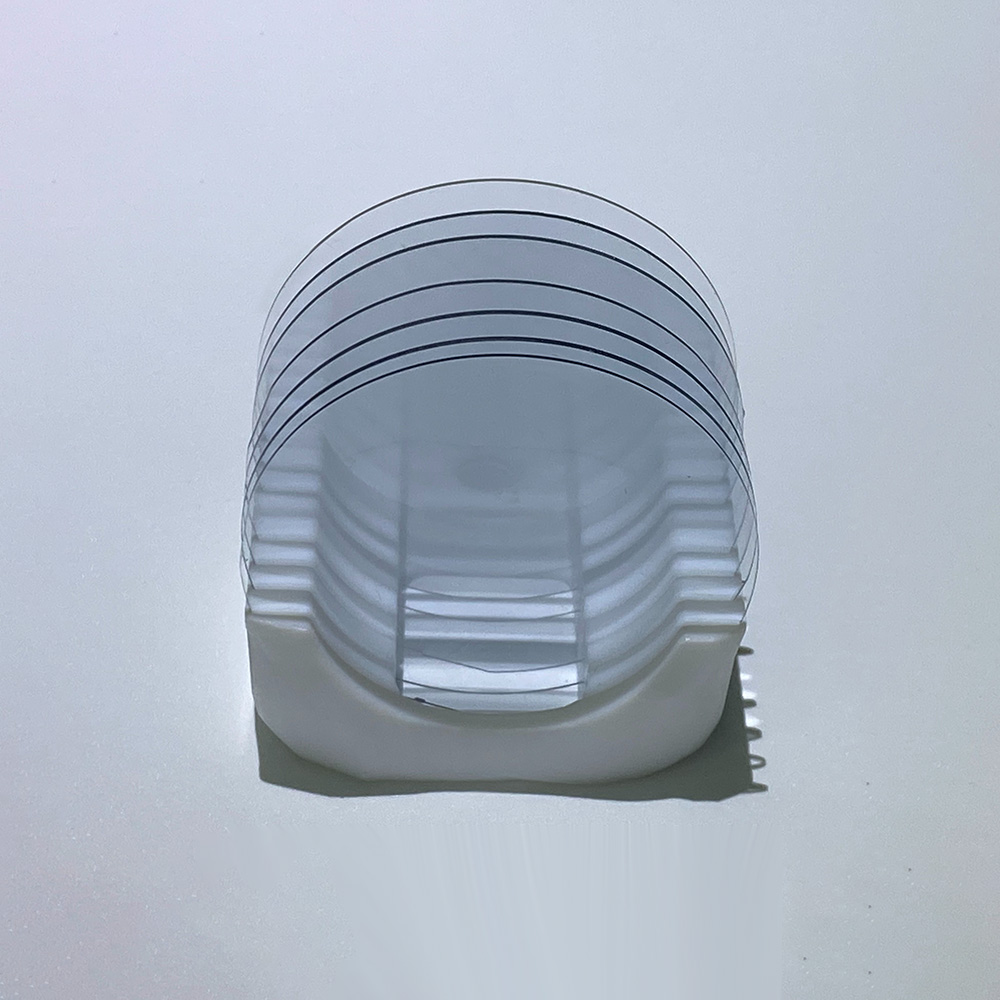

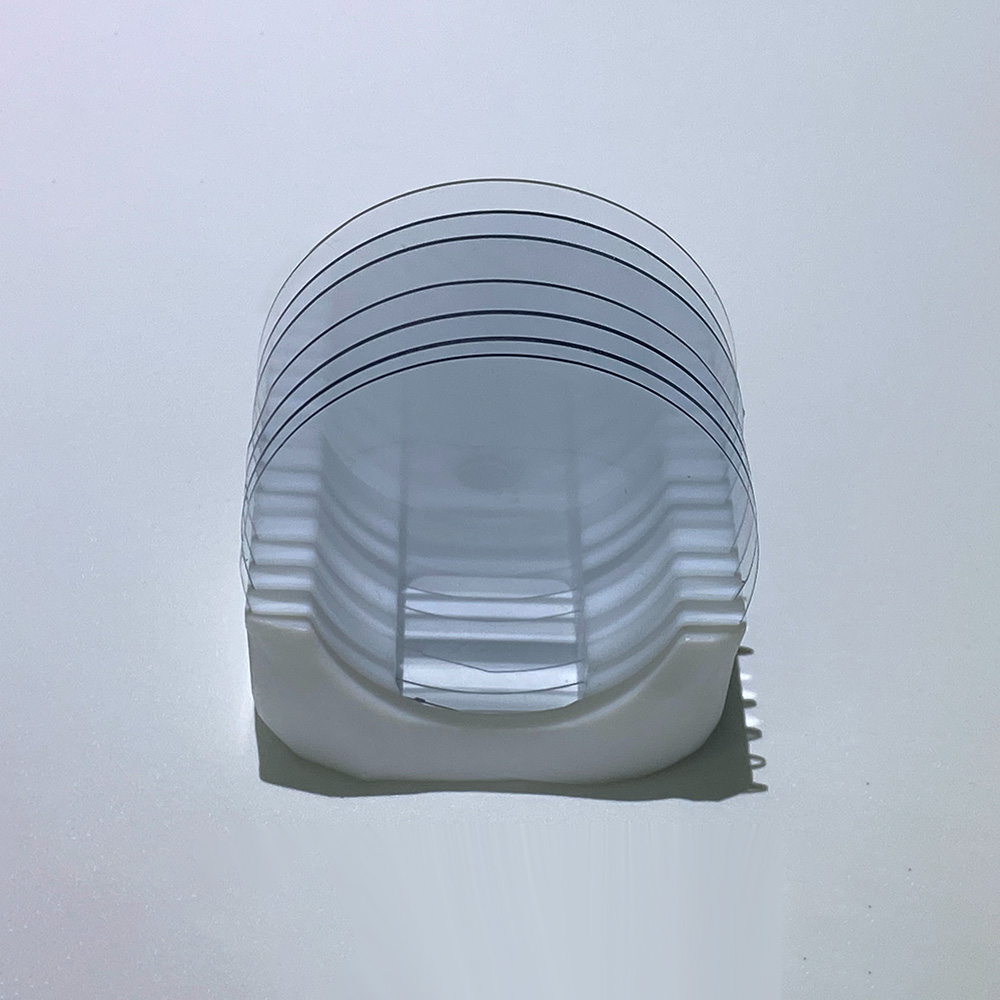

Packaging and Transportation

The packaging should be able to withstand the impact, vibration, stacking and extrusion that may be encountered during transportation, while also it has to easy to load, unload and handle.

We use professional wafer box packaging. The wafer box is protected by a double layer bag, the inside is a PE bag that can be dust-proof, and the outside is a aluminum foil bag that can be isolated from the air. The two-layer bags are vacuum-packed.

We will choose carton models according to different sizes of products. And between the product and the carton filled with shock-proof EPE foam, play a comprehensive protection.

Finally choose air transport to reach the customer's hands. This allows customers in any country and region to receive the product in the fastest time.

We comply with the Material Safety Data Sheet (MSDS) rules to ensure that the products transported are free of harmful substances and will not cause environmental pollution and explosion and other possible hazards.

Enterprise Strength

Factory Area: 3000 sq

Process:

1. Shaping→2. Edge Profile→3. Lapping→4. Polishing→5. Cleaning→6. Packing→7. Transportation

Capacity:

Glass Wafer --- 30K pcs

Silicon Wafer --- 20K pcs

(Equal to 6in)

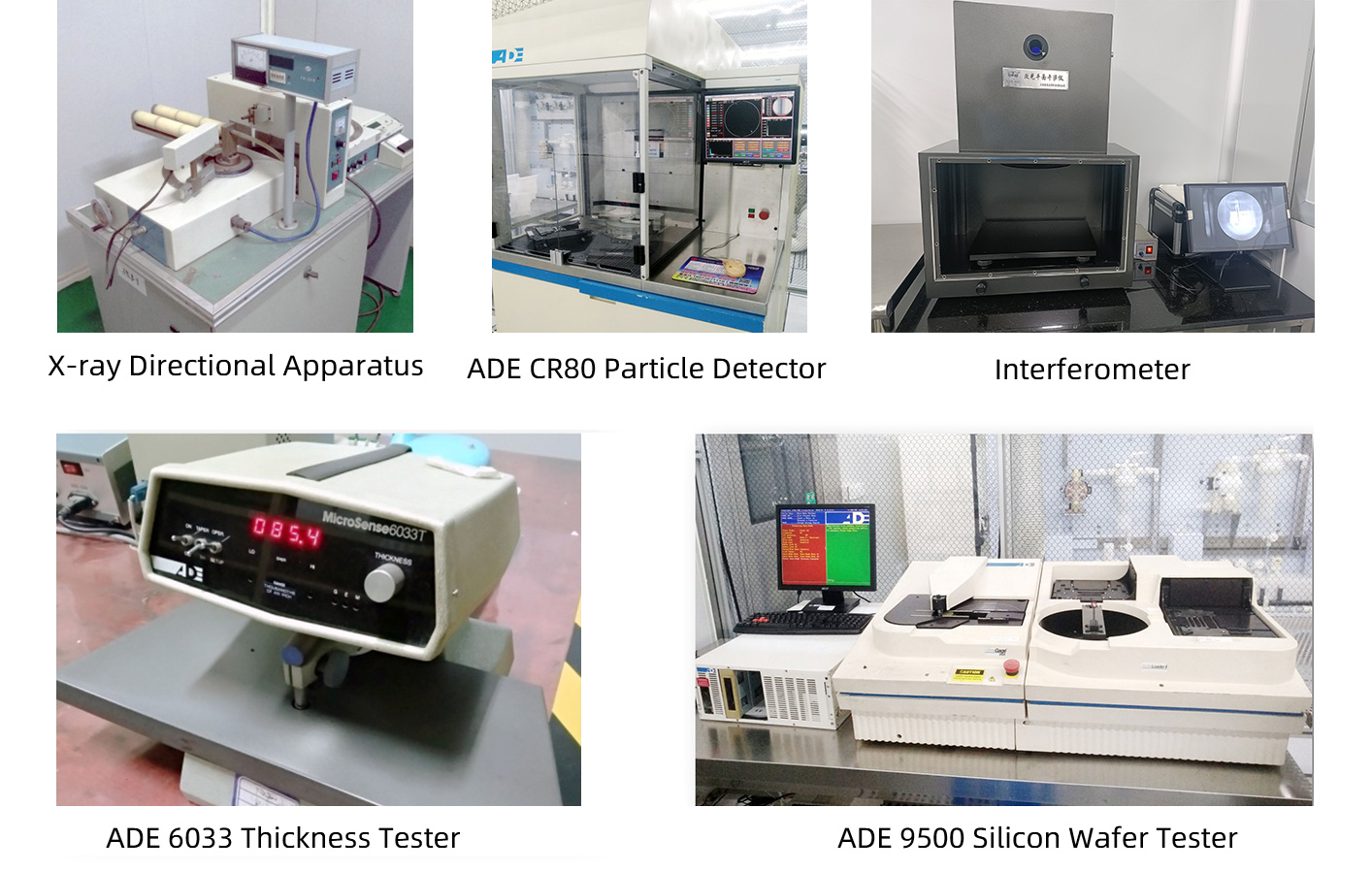

Quality Assurance

Quality inspection method: Product inspection in accordance with SEMI standard or according to customer's requirements, together with product COA.

Warranty period: In accordance with the contract requirements.

Quality system management:

●Organize production according to ISO9001 and other quality system standards.

Quality management system and measures:

●Establish a strict quality assurance system, the heads of all departments and quality engineers to ensure the coordinated operation of the quality system.

●Strengthen the quality inspection system, strengthen the process quality control

●Strict material quality control, ensure that the input materials meet the design requirements and technical specifications.

●Implement a timely filing system for technical data to ensure that all processing technical data is complete/accurate.

Quality control in the production stage:

●Production preparation stage: carefully organize relevant personnel to learn product drawings and technical rules, and improve the technical level of employees.

●Quality control of the production process: the implementation of a strict handover system, the previous step of the process to the next step of the transfer, should be detailed processing. At the same time, strengthen the quality inspection system to ensure the quality of each step of the process.

●Quality acceptance: All processes must be quality acceptance before proceeding to the next process.

Pre-sales and After-sales

Pre-sales Service

Professional technical support and commercial team to help you determine product specifications according to product use, and issue specifications.

On-purchase Service

Produce products according to the confirmed specifications and our process.

After Sale Service

We will respond to any product problems encountered by customers or process problems encountered by customers within 24 hours. We can choose from various forms of service, such as email, video conference and so on.

Plutosemi Co., Ltd. was established in 2019, headquartered in Nanhai, Foshan, focusing on the research and development, production, and sales of high-performance semiconductor materials.

Advanced production capacity: We have three major production bases in China, with a monthly production capacity of 100000 equivalent 6-inch silicon wafers and 30000 equivalent 8-inch glass wafers, ensuring stable and efficient product supply for our customers.

High quality products: We provide efficient and stable product supply innovative solutions in the fields of glass wafers, silicon polishing wafers, epitaxial wafers (EPI), silicon on insulator wafers (SOI), and more. Our silicon wafers have the characteristics of ultra-thin, ultraflat, and high-precision, which can meet the needs of various high-end applications. Our glass and quartz substrates are also renowned for their high smoothness and precise aperture design.