Semiconductor Dummy Wafer

Silicon Wafer

-

+86-17701852595 WhatsApp

-

sales@plutosemitech.com Email

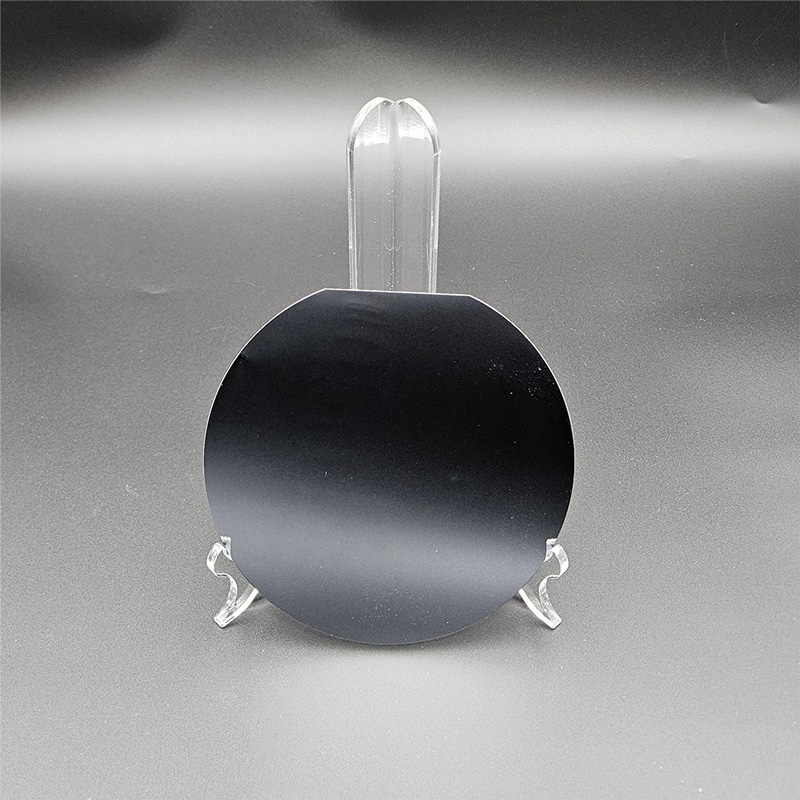

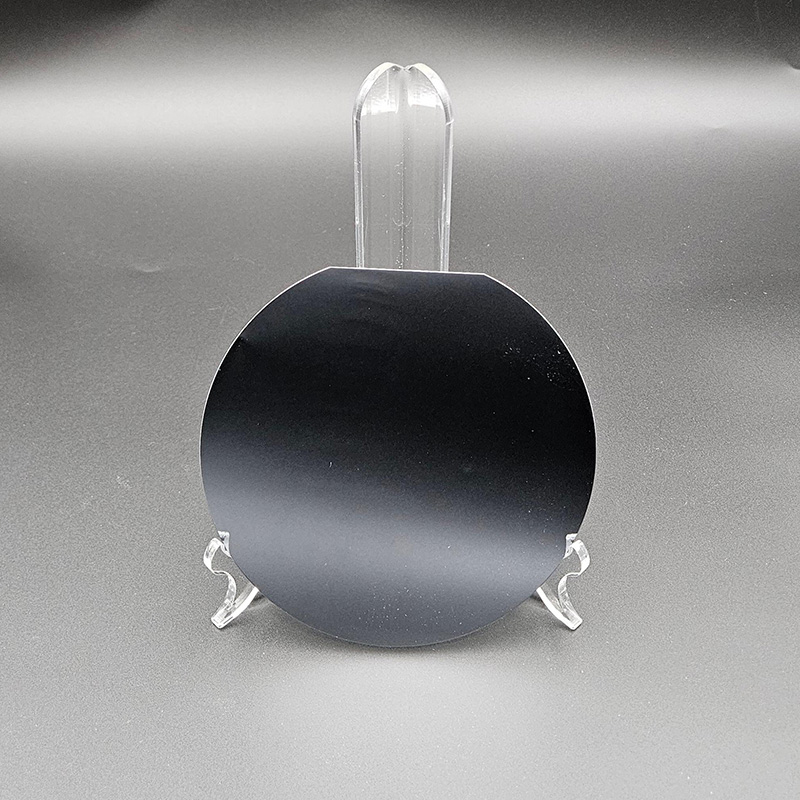

Dummy Wafer is a tool used in the manufacturing field to simulate the behavior of real wafers. It is not used for the production of the final product, but as a substitute in the testing, calibration, or equipment validation process. Dummy Wafer is very similar in appearance and size to a real wafer, but it does not contain any actual circuit or device structure inside. The original intention of its design is to simulate the physical and chemical properties of real wafers in the manufacturing process, help engineers evaluate equipment performance, optimize process parameters, and ensure the stability and reliability of the production line.

Semiconductor Dummy Wafer Specifications

| Item | Specifications | ||

| Diameter | 150mm | 200mm | 300mm |

| Type | P/N | P/N | P/N |

| Notch | SEMI/JEIDA | Notch/OF | Notch |

| Thickness | 675±25/625±25μm | 725±25μm | 775±25μm |

| Frontside | Polished | Polished | Polished |

| Backside | Etched | Etched | Etched |

| OEM/ODM | Accept | ||

| Compay Nature | China Manufacturers Suppliers Factory | ||

Semiconductor Dummy Wafer Features

1. Diverse sizes: PLUTO offers a wide range of Dummy Wafer sizes, ranging from 2 inches to 12 inches. This comprehensive size coverage can meet the diverse needs of different production lines for wafer sizes. Whether it is a small experimental production line or a large industrial production line, Dummy Wafer can be found here, providing great convenience and flexibility for various semiconductor manufacturing projects.

2. Stable quality: PLUTO has its own factory, which enables every Dummy Wafer to undergo strict and systematic quality control processes. From the screening of raw materials to every step of the production process, and even to the final inspection of finished products, we adhere to high standards of quality management regulations. This comprehensive quality control ensures the stability and reliability of Dummy Wafer quality, allowing customers to apply it to various testing and verification processes without worrying about quality issues during use.

3. Controllable delivery: Our own production system has brought PLUTO a high degree of controllability in delivery time. By optimizing the production process, arranging production plans reasonably, and efficient logistics management, PLUTO can ensure that customers can obtain the required products in a timely manner. The controllability of this delivery is crucial for the client's project schedule, as it can help them avoid project delays caused by product delivery delays and improve overall project execution efficiency.

4. Customized services: PLUTO understands that different customers have specific needs in the semiconductor manufacturing process, and therefore provides customized Dummy Wafer solutions. Whether it is special size requirements, material selection, or surface treatment processes, PLUTO can customize production according to the specific needs of customers. This customized service can meet the personalized needs of customers and provide more targeted support in the semiconductor manufacturing field.

5. High precision simulation: PLUTO strives to make Dummy Wafer consistent with real wafers in terms of material selection and surface treatment, in order to achieve high-precision simulation. By selecting materials similar to real wafers and utilizing advanced surface treatment techniques, Dummy Wafer is able to accurately simulate the physical and chemical properties of real wafers during the manufacturing process. This high-precision simulation enables Dummy Wafer to have higher reliability and accuracy in equipment calibration, process optimization, and other aspects.

6. Easy to handle: When designing Dummy Wafer, PLUTO fully considered operational convenience. Its unique structure and design make Dummy Wafer easy to pick up, place, and transport during testing, reducing the labor intensity of operators and improving testing efficiency. At the same time, this easy to handle feature also reduces the risk of damage to Dummy Wafer during operation, further ensuring the accuracy and reliability of testing.

Semiconductor Dummy Wafer Process Flow

The process flow of Semiconductor Dummy Wafer mainly includes the following steps: first, select suitable substrate materials according to customer needs and perform pretreatment to ensure surface flatness and cleanliness; Next, the desired patterns and structures are formed on the substrate through processes such as photolithography and etching; Then, surface treatment such as coating, polishing, etc. is carried out to improve the simulation accuracy and durability of Dummy Wafer; Finally, strict quality testing is conducted to ensure that every Dummy Wafer meets customer requirements and relevant standards. The entire process is completed within our own factory, ensuring the controllability of product quality and delivery time.

Semiconductor Dummy Wafer Application

1. Equipment calibration: The accuracy and stability of equipment are crucial in the semiconductor manufacturing process. Dummy Wafer, as an important tool for equipment calibration and verification, can simulate the operating status of real wafers in the equipment, helping engineers accurately evaluate the performance of the equipment. By using Dummy Wafer for equipment calibration, it is possible to ensure the accuracy of various parameters during the manufacturing process, thereby improving product quality and production efficiency.

2. Process optimization: Dummy Wafer plays a crucial role as a test sample in developing new processes or optimizing existing processes. Engineers can adjust and optimize various process parameters on Dummy Wafer, observe and analyze the impact of different parameters on the wafer manufacturing process. This Dummy Wafer based process optimization method can reduce the risk and cost of directly operating real wafers, while improving the efficiency and success rate of process development.

3. Production line testing: Regular testing on the production line is an important means of evaluating the stability and reliability of the production line. Dummy Wafer can be used as a test sample to simulate the operation process of real wafers on the production line, helping engineers discover problems and hidden dangers in the production line in a timely manner. Regular testing and evaluation of the production line can ensure its stable operation, improve product yield and production efficiency.

4. Training and teaching: For new employees, quickly familiarizing themselves with semiconductor manufacturing processes and operating standards is crucial. Dummy Wafer, as a teaching tool, can visually demonstrate the various stages and operational points in the wafer manufacturing process. Through practical operation of Dummy Wafer, new employees can gain a deeper understanding of the principles and processes of semiconductor manufacturing, and improve their operational skills and levels.

5. Quality control: Using Dummy Wafer in the quality control process can ensure that the product meets relevant standards and requirements. By conducting various tests and inspections on Dummy Wafer, the quality control effectiveness during the production process can be evaluated, and quality issues can be identified and corrected in a timely manner. This Dummy Wafer based quality control method can improve product quality and stability, enhance customer trust and satisfaction with the product.

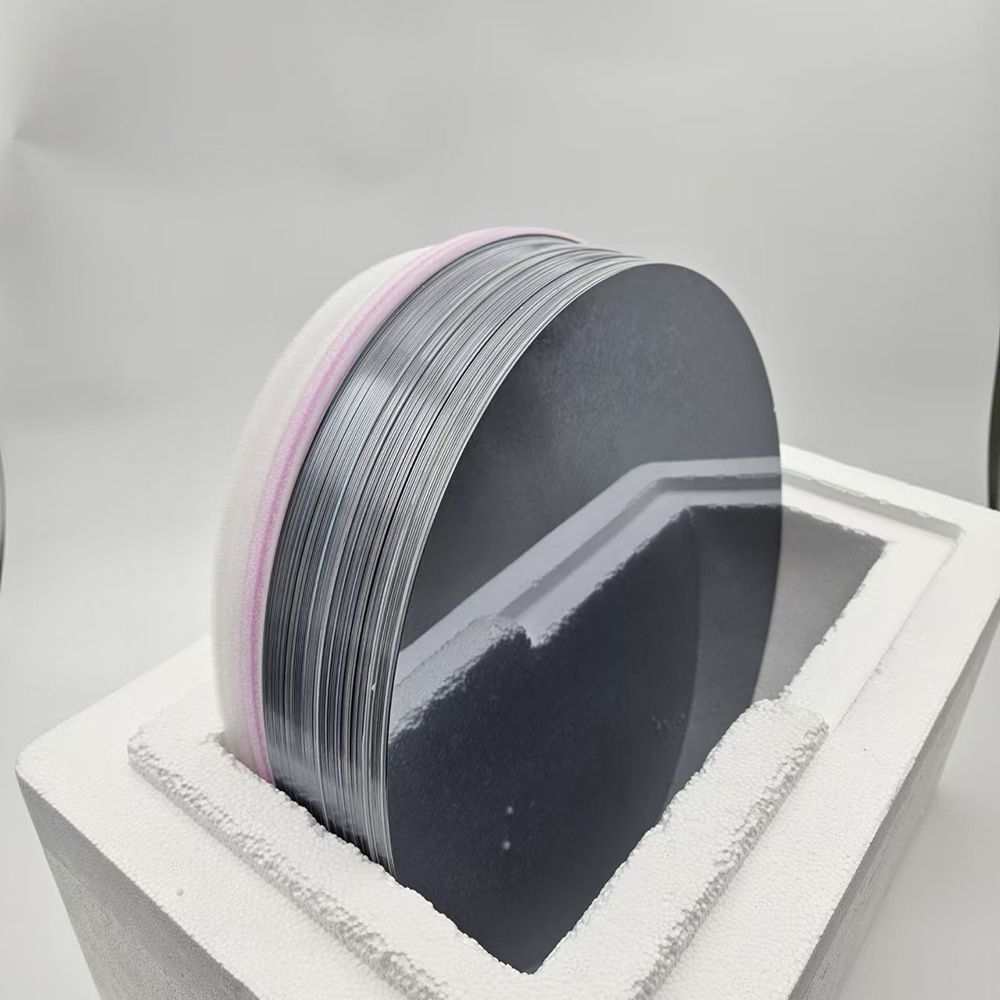

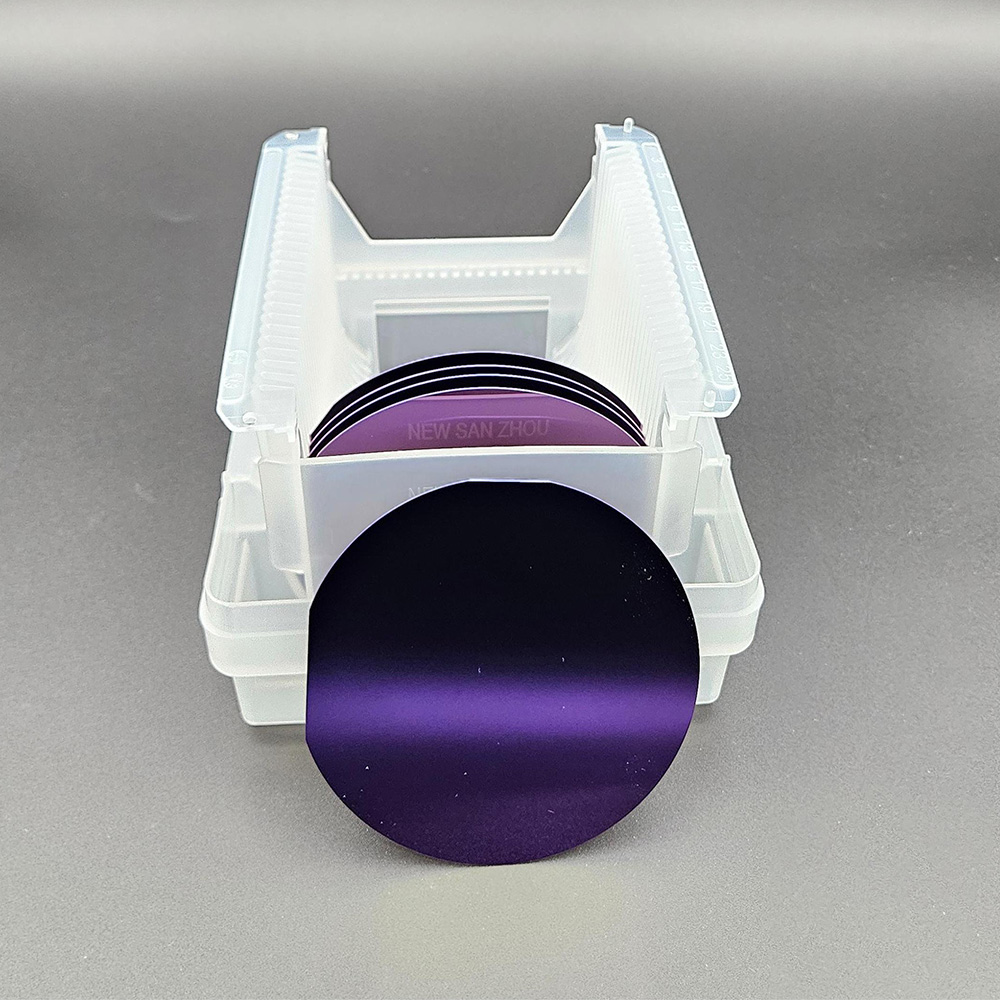

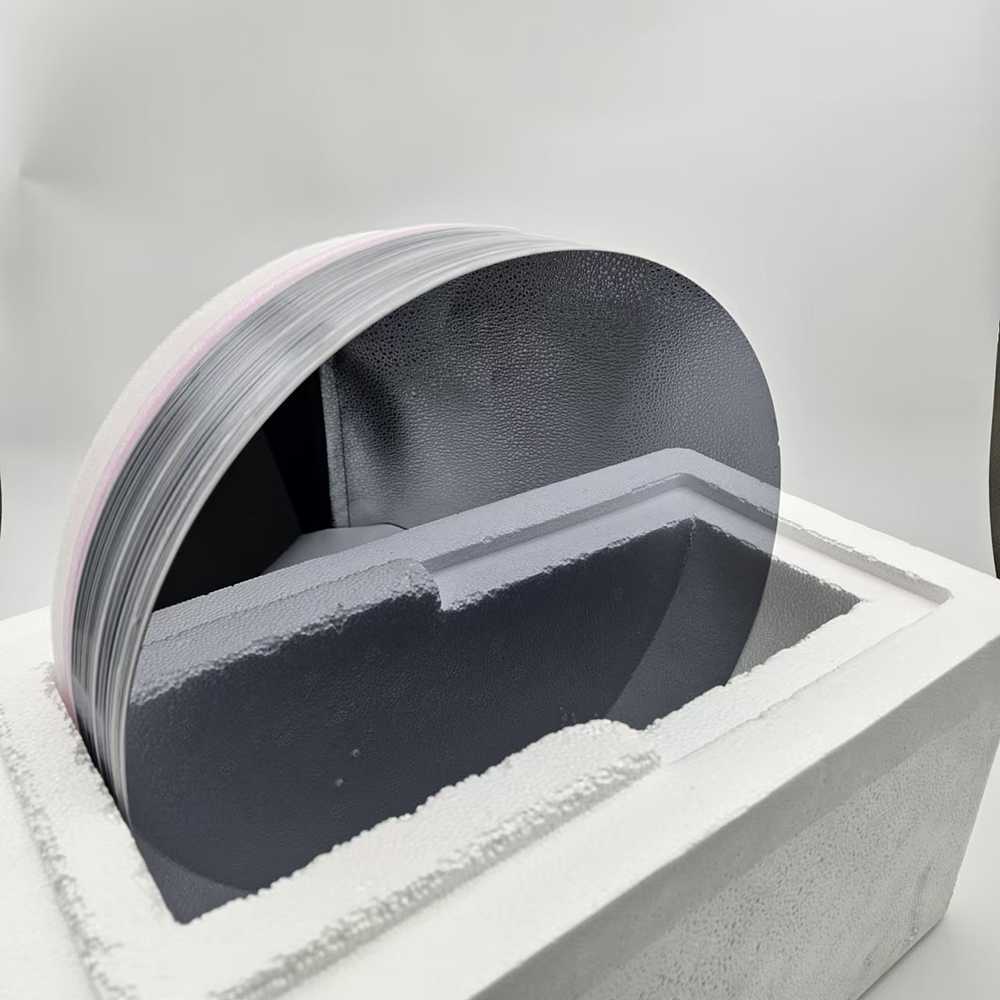

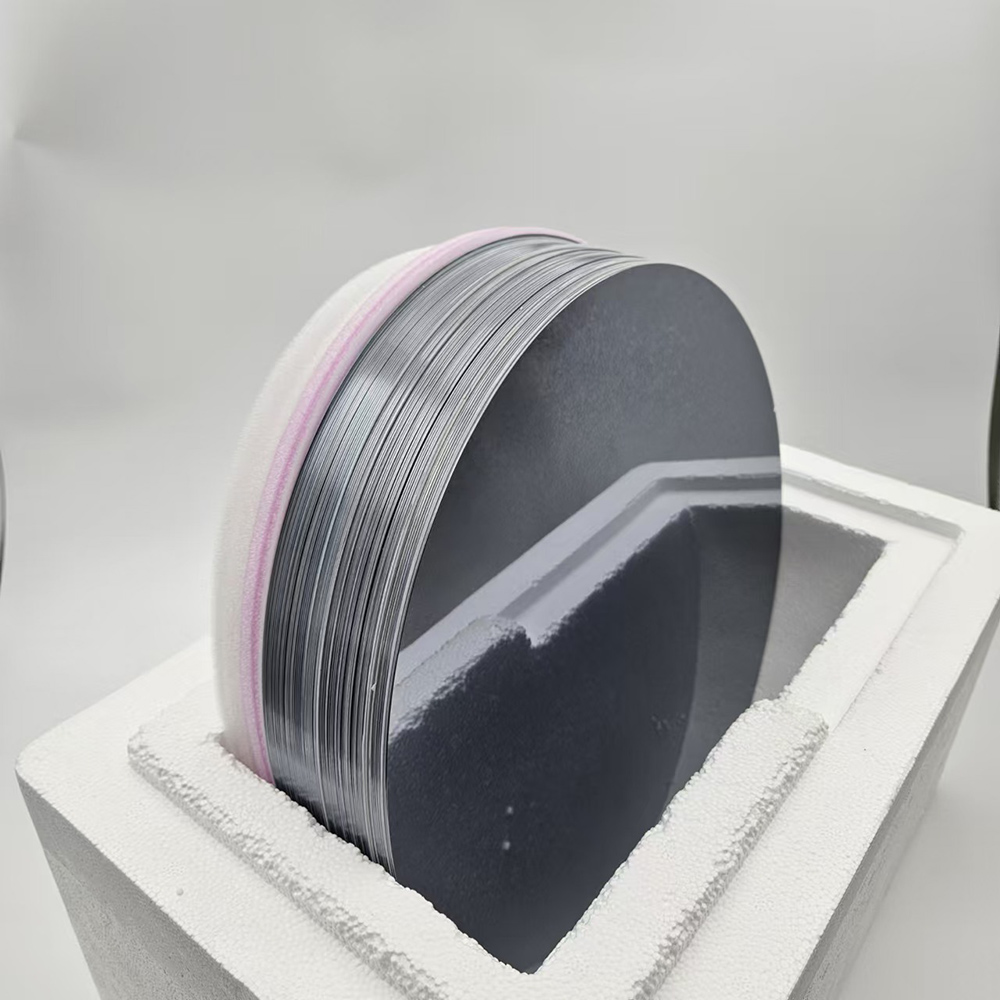

Packaging and Transportation

The packaging should be able to withstand the impact, vibration, stacking and extrusion that may be encountered during transportation, while also it has to easy to load, unload and handle.

We use professional wafer box packaging. The wafer box is protected by a double layer bag, the inside is a PE bag that can be dust-proof, and the outside is a aluminum foil bag that can be isolated from the air. The two-layer bags are vacuum-packed.

We will choose carton models according to different sizes of products. And between the product and the carton filled with shock-proof EPE foam, play a comprehensive protection.

Finally choose air transport to reach the customer's hands. This allows customers in any country and region to receive the product in the fastest time.

We comply with the Material Safety Data Sheet (MSDS) rules to ensure that the products transported are free of harmful substances and will not cause environmental pollution and explosion and other possible hazards.

Enterprise Strength

Factory Area: 3000 sq

Process:

1. Shaping→2. Edge Profile→3. Lapping→4. Polishing→5. Cleaning→6. Packing→7. Transportation

Capacity:

Glass Wafer --- 30K pcs

Silicon Wafer --- 20K pcs

(Equal to 6in)

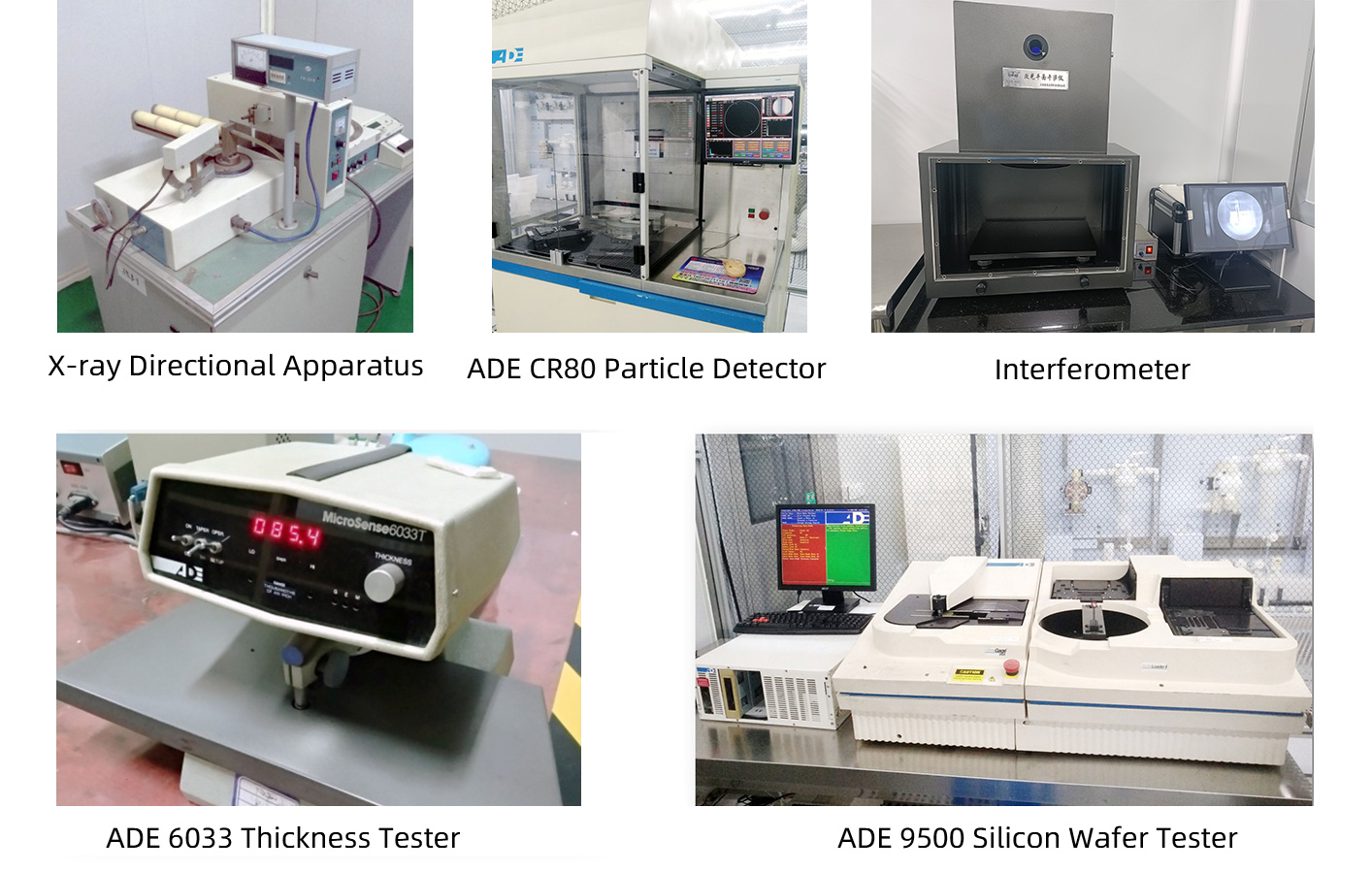

Quality Assurance

Quality inspection method: Product inspection in accordance with SEMI standard or according to customer's requirements, together with product COA.

Warranty period: In accordance with the contract requirements.

Quality system management:

●Organize production according to ISO9001 and other quality system standards.

Quality management system and measures:

●Establish a strict quality assurance system, the heads of all departments and quality engineers to ensure the coordinated operation of the quality system.

●Strengthen the quality inspection system, strengthen the process quality control

●Strict material quality control, ensure that the input materials meet the design requirements and technical specifications.

●Implement a timely filing system for technical data to ensure that all processing technical data is complete/accurate.

Quality control in the production stage:

●Production preparation stage: carefully organize relevant personnel to learn product drawings and technical rules, and improve the technical level of employees.

●Quality control of the production process: the implementation of a strict handover system, the previous step of the process to the next step of the transfer, should be detailed processing. At the same time, strengthen the quality inspection system to ensure the quality of each step of the process.

●Quality acceptance: All processes must be quality acceptance before proceeding to the next process.

Pre-sales and After-sales

Pre-sales Service

Professional technical support and commercial team to help you determine product specifications according to product use, and issue specifications.

On-purchase Service

Produce products according to the confirmed specifications and our process.

After Sale Service

We will respond to any product problems encountered by customers or process problems encountered by customers within 24 hours. We can choose from various forms of service, such as email, video conference and so on.

Plutosemi Co., Ltd. was established in 2019, headquartered in Nanhai, Foshan, focusing on the research and development, production, and sales of high-performance semiconductor materials.

Advanced production capacity: We have three major production bases in China, with a monthly production capacity of 100000 equivalent 6-inch silicon wafers and 30000 equivalent 8-inch glass wafers, ensuring stable and efficient product supply for our customers.

High quality products: We provide efficient and stable product supply innovative solutions in the fields of glass wafers, silicon polishing wafers, epitaxial wafers (EPI), silicon on insulator wafers (SOI), and more. Our silicon wafers have the characteristics of ultra-thin, ultraflat, and high-precision, which can meet the needs of various high-end applications. Our glass and quartz substrates are also renowned for their high smoothness and precise aperture design.