Polypropylene Single Silicon Wafer Shipper

Silicon Wafers Packing

-

+86-17701852595 WhatsApp

-

sales@plutosemitech.com Email

The Polypropylene Single Silicon Wafer Shipper is expertly designed to securely transport and store silicon wafers, ensuring maximum protection during handling. This versatile shipper accommodates wafers of various sizes, including 50.8mm (2”), 76.2mm (3”), 100mm (4”), and 150mm (6”), making it an ideal solution for wafer storage and transportation in industries where precision and safety are paramount. Crafted from durable polypropylene, it provides superior resistance to impacts, ensuring wafers remain intact and contamination-free. Its innovative structure guarantees easy loading and unloading, while maintaining a firm grip on wafers to prevent movement during transit. For businesses seeking reliable packaging solutions, the China single silicon wafer shipper wholesale market offers high-quality options at competitive prices.

Polypropylene Single Silicon Wafer Shipper Specifications

●50.8mm silicon wafer packing

●76.2mm silicon wafer packing

●100mm silicon wafer packing

●150mm silicon wafer packing

Polypropylene Single Silicon Wafer Shipper Features

1. Versatile Size Compatibility: Designed to fit multiple wafer sizes: 50.8mm (2”), 76.2mm (3”), 100mm (4”), and 150mm (6”), meeting the needs of various applications.

2. High-Quality Material: Made of durable polypropylene, ensuring excellent impact resistance and long-lasting performance.

3. Secure Protection: Provides robust protection for wafers, preventing damage and contamination during transportation and storage.

4. Wide Application: Suitable for both silicon wafer transportation and storage, making it ideal for semiconductor and electronics industries.

Packaging and Transportation

The packaging should be able to withstand the impact, vibration, stacking and extrusion that may be encountered during transportation, while also it has to easy to load, unload and handle.

We use professional wafer box packaging. The wafer box is protected by a double layer bag, the inside is a PE bag that can be dust-proof, and the outside is a aluminum foil bag that can be isolated from the air. The two-layer bags are vacuum-packed.

We will choose carton models according to different sizes of products. And between the product and the carton filled with shock-proof EPE foam, play a comprehensive protection.

Finally choose air transport to reach the customer's hands. This allows customers in any country and region to receive the product in the fastest time.

We comply with the Material Safety Data Sheet (MSDS) rules to ensure that the products transported are free of harmful substances and will not cause environmental pollution and explosion and other possible hazards.

Enterprise Strength

Factory Area: 3000 sq

Process:

1. Shaping→2. Edge Profile→3. Lapping→4. Polishing→5. Cleaning→6. Packing→7. Transportation

Capacity:

Glass Wafer --- 30K pcs

Silicon Wafer --- 20K pcs

(Equal to 6in)

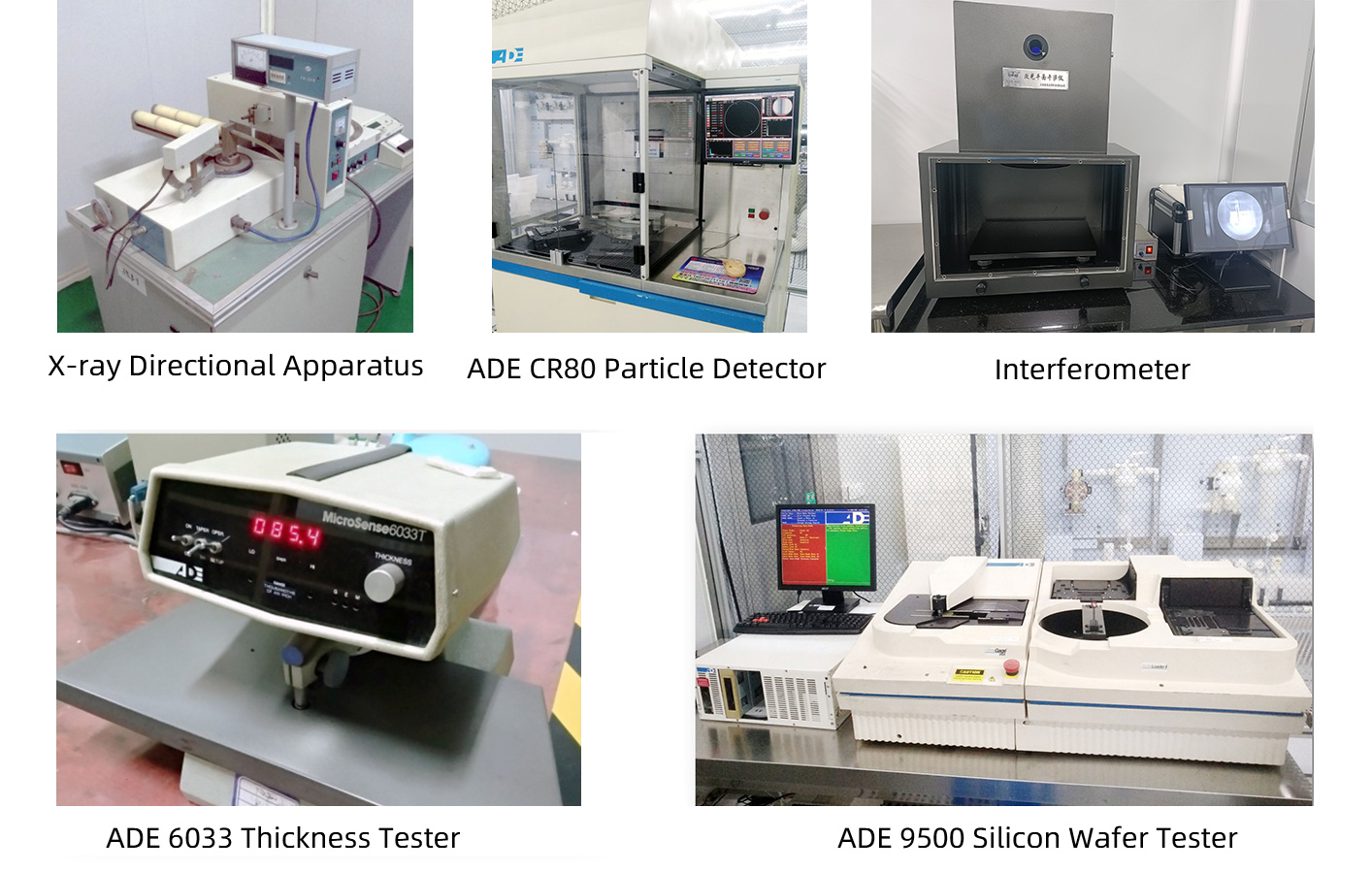

Quality Assurance

Quality inspection method: Product inspection in accordance with SEMI standard or according to customer's requirements, together with product COA.

Warranty period: In accordance with the contract requirements.

Quality system management:

●Organize production according to ISO9001 and other quality system standards.

Quality management system and measures:

●Establish a strict quality assurance system, the heads of all departments and quality engineers to ensure the coordinated operation of the quality system.

●Strengthen the quality inspection system, strengthen the process quality control

●Strict material quality control, ensure that the input materials meet the design requirements and technical specifications.

●Implement a timely filing system for technical data to ensure that all processing technical data is complete/accurate.

Quality control in the production stage:

●Production preparation stage: carefully organize relevant personnel to learn product drawings and technical rules, and improve the technical level of employees.

●Quality control of the production process: the implementation of a strict handover system, the previous step of the process to the next step of the transfer, should be detailed processing. At the same time, strengthen the quality inspection system to ensure the quality of each step of the process.

●Quality acceptance: All processes must be quality acceptance before proceeding to the next process.

Pre-sales and After-sales

Pre-sales Service

Professional technical support and commercial team to help you determine product specifications according to product use, and issue specifications.

On-purchase Service

Produce products according to the confirmed specifications and our process.

After Sale Service

We will respond to any product problems encountered by customers or process problems encountered by customers within 24 hours. We can choose from various forms of service, such as email, video conference and so on.

Plutosemi Co., Ltd. was established in 2019, headquartered in Nanhai, Foshan, focusing on the research and development, production, and sales of high-performance semiconductor materials.

Advanced production capacity: We have three major production bases in China, with a monthly production capacity of 100000 equivalent 6-inch silicon wafers and 30000 equivalent 8-inch glass wafers, ensuring stable and efficient product supply for our customers.

High quality products: We provide efficient and stable product supply innovative solutions in the fields of glass wafers, silicon polishing wafers, epitaxial wafers (EPI), silicon on insulator wafers (SOI), and more. Our silicon wafers have the characteristics of ultra-thin, ultraflat, and high-precision, which can meet the needs of various high-end applications. Our glass and quartz substrates are also renowned for their high smoothness and precise aperture design.