TGV Process Services

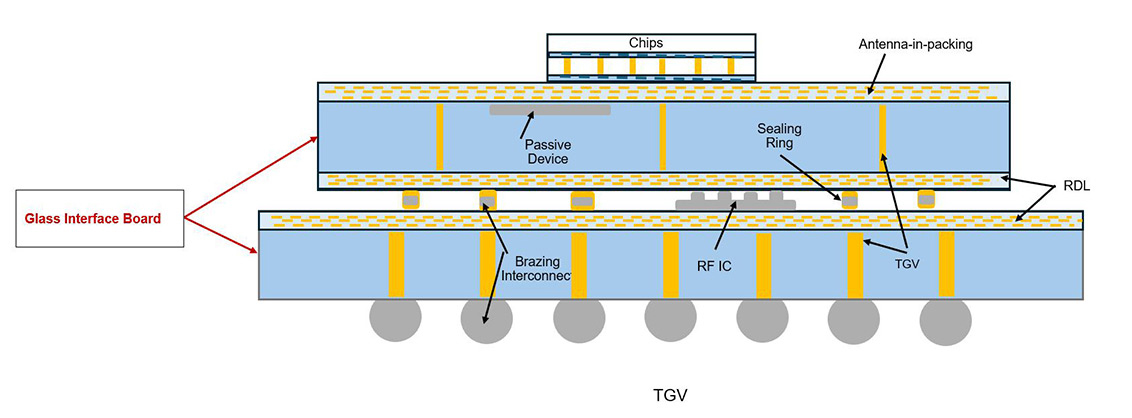

TGV (Through Glass Via) technology is a vertical electrical interconnect through glass substrate. It creates vertical electrical connections on the glass substrate, enabling high-density interconnections from chip to chip and chip to substrate.

The intermediary layer traversed on a silicon adapter board is TSV technology, while the intermediary layer traversed on a glass adapter board is TGV. TGV and related technologies have a wide range of applications in the fields of optical communications, radio frequency, MEMS, microfluidic devices, and three-dimensional integration.

Our Processes:

Pre-preparation:

Clean the glass substrate and make sure the surface is free of dust and stains.

Edit the appropriate graphics according to the design requirements.

Select suitable laser equipment.

Laser perforation:

The use of a laser device to scan across the glass in a predetermined pattern and parameters.

The laser instantly heats and vaporises the glass material, thus creating tiny holes in the surface.

Deep holes are created by picosecond pulsed lasers that produce successive denaturation zones in the glass, which are preferentially removed during the subsequent etching process.

Etch treatment:

The laser-treated area is etched using a chemical etching solution to further enlarge and deepen the holes.

The size and shape of the holes can be controlled by adjusting the composition of the etchant and the processing time.

Through-hole formation:

Through-holes are formed in the etched glass substrate, which can be used to connect circuits or components between different layers.

Subsequent processing:

Cleaning of etching solution and other impurities left inside the holes.

Quality Inspection:

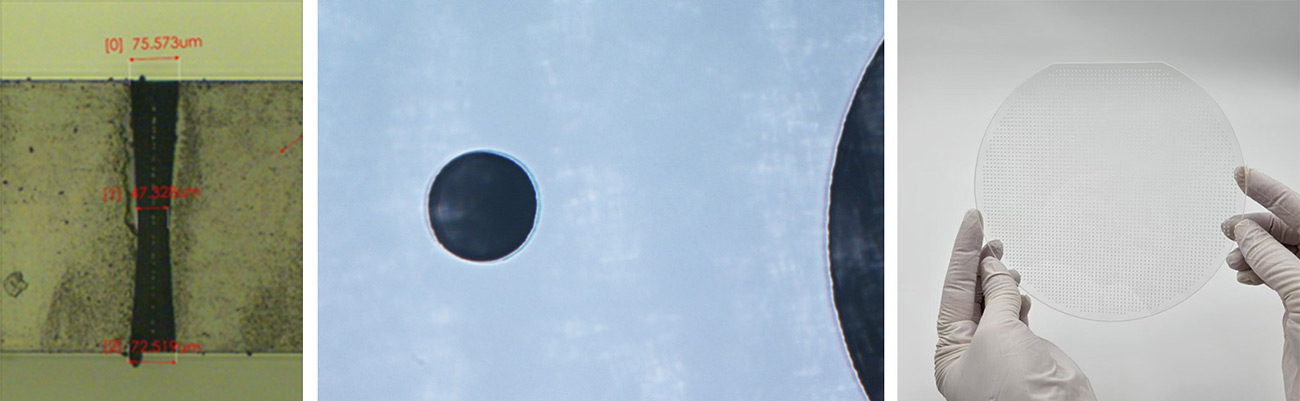

Use optical microscope, scanning electron microscope and other equipment to accurately measure and inspect the size, shape and location of the through-hole.

Confirm that the through-hole meets design specifications and usage requirements.